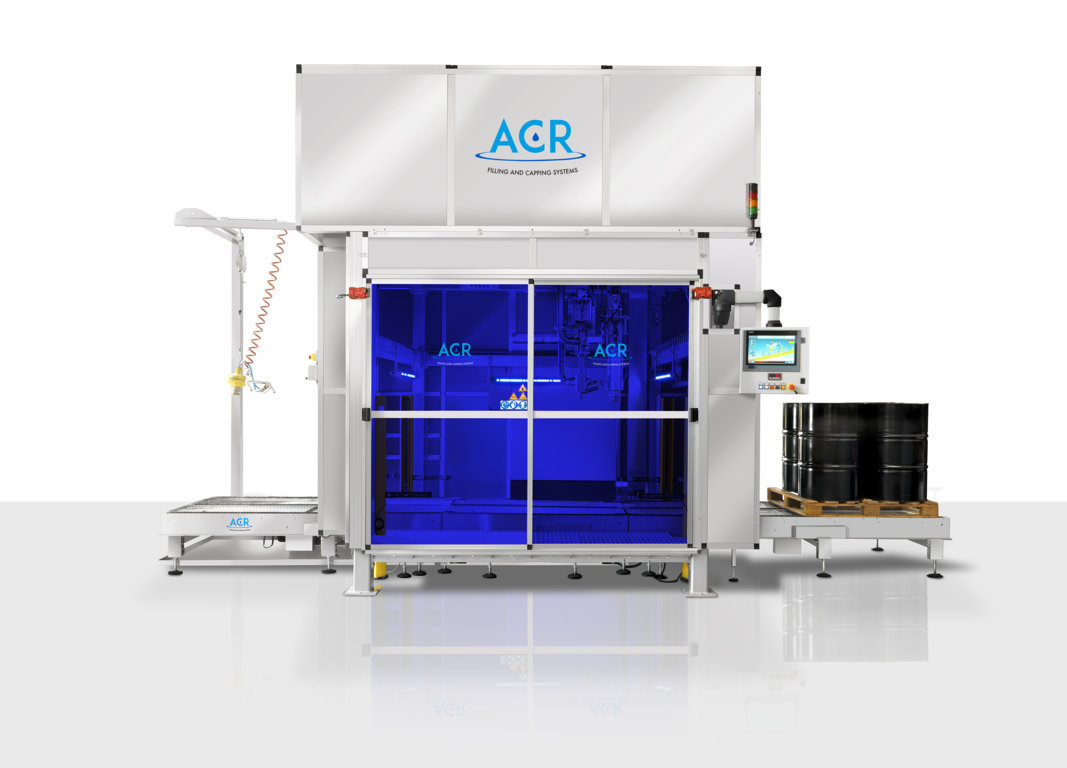

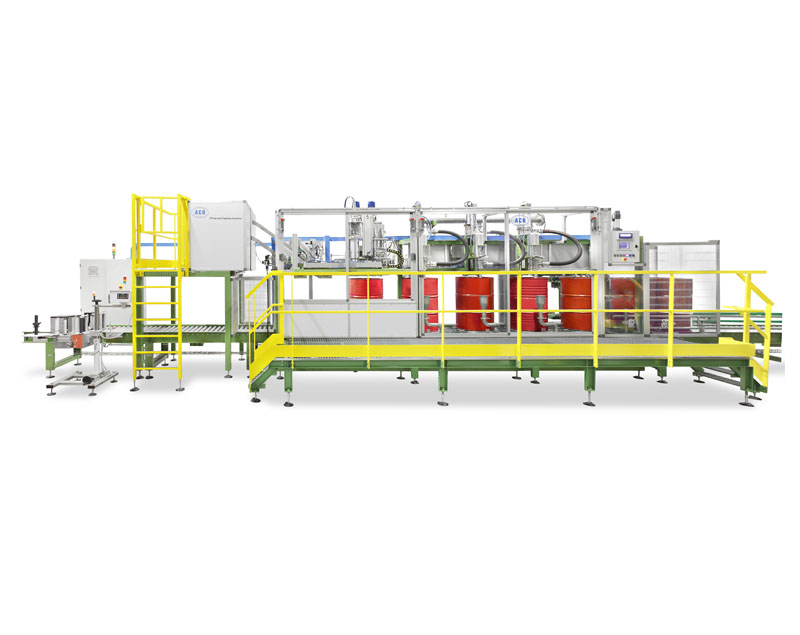

Like all machinery and equipment offered by ACR Filling and Capping Systems, the IBC and drum fillings machines are designed and manufactured to provide a reliable and high quality product, equipped with the latest technology and quality materials.

The IBC and drum filling machines provided by ACR fully comply with the latest European and international standards.